SUSTAINABILITY UPDATE

22 February 2019

Some of our recent sustainability initiatives

Achieving sustainability is a journey, not a destination – there is no one single action that will deliver the Holy Grail of sustainability – rather a series of improvements in all areas of business.

At Dechra, we have a series of projects, some large and some small but each moving us toward improved sustainability.

Each project has a team of people working to achieve clear and measurable targets with detailed timescales, regularly reporting on progress to our senior managers.

Some improvements that we have been working on over the last 12 months have been improvements to:

-

Sustainability of our packaging

-

Sustainability of our recipes and ingredients

-

Sustainability of our warehousing and distribution

-

Sustainability of our manufacturers

In 2018 we changed the packaging of our cat food, reducing bag height; using thinner bags and introducing a flat bottom. This reduced plastic use by 3,000kgs. In 2019, we will be making the same changes to our range of dog food to is projected to save a further 18,000kgs of plastic.

Our cardboard cartons are now FSC certified

Reducing the quantity of packaging is a start but what we would really like is fully recyclable or, even better, biodegradable packaging. The challenge we face is that we have to use packaging that protects the product inside in order to reduce levels of food waste. We have a number of ongoing projects researching and testing new and more sustainable packaging materials.

RECIPES AND INGREDIENTS

All of the krill and the fish oil used in the dry SPECIFIC diets are certified by either Marine Stewardship Council (MSC) or IFFO RS Standard. All of the fish meal used in our dry cat food is certified by IFFO RS Standard and the fish meal in the dry dog food will be replaced with fish from accredited sources in 2019. We are aiming to move to 100% of our fish from certified sustainable sources in 2019.

There are some exciting new ingredients that offer improved sustainability that we are starting to work with. Algae, which is used in our new sardine cat food, is one such ingredient. Algae are a rich source of omega-3 and it’s because fish eat algae that they are rich in omega-3. Directly using algae as an ingredient has a number of benefits. Commercial algae production takes place on shore, so has no impact on the marine environment; it uses a highly controlled process that takes very little land and does not use valuable drinking water or arable soil and, lastly, directly using algae as an ingredient helps preserve fish stocks.

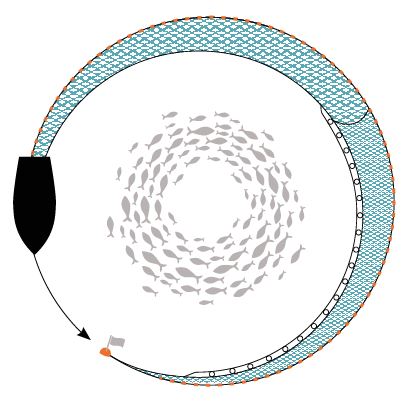

As well as ensuring the provenance of our ingredients we are also interested in how these ingredients are produced. The sardine used in our new cat food are caught, in MSC certified fisheries, using a low impact ring netting system. With trawl netting the nets are towed through the water. With ring netting, a net is used to encircle a shoal of fish forming a deep curtain of netting suspended vertically through the water - the net is then drawn in.

There are a number of advantages to ring netting:

-

By-catch is reduced – if the wrong species is in the net the whole catch can be released, unharmed, before it is landed.

-

Less seabed impact as the net does not come into contact with the seabed

-

Lower fuel consumption as a ring net is not towed through the water and the vessels used are small inshore vessels.

MANUFACTURERS

Our pet food is produced by a number of manufacturers under our control.

Most of our wet food is produced in Denmark and our organic wet food in Austria. These plants are aiming to achieve zero landfill, CO2 reduction/energy reduction, water usage reduction and have set targets to ensure efficient utilisation of resources.

Most of our dry foods are produced in Belgium. This plant has worked actively at reducing the ecological footprint on a yearly basis. They produce their own electricity via solar panels with an annual yield of 65.000 kWh. All the different kinds of waste are sorted out and treated separately and more than 95% of all the waste is recycled by recognized and reliable partners.

Some of our new cat foods are produced in a plant in the UK where 68% of their electricity is provided from an anaerobic digester, using waste materials from the pet food plant and the neighbouring farm – a further 3% of electricity comes from solar panels.

WAREHOUSING AND DISTRIBUTION

Our warehousing and distribution centre in Uldum, Denmark is a huge international operation handling 45,000 deliveries to customers worldwide and receiving and storing 1,300 full truck deliveries a year. The main sources of emissions are transportation and use of energy (electricity and heating) for the operation of the warehouse.

TRANSPORT

Key to our management of this area is measurement. If you can’t measure it, you can’t improve it. We work with a small number of selected transport companies and a condition for working with us is that we receive monthly information on the carbon footprint of the transports of our products.

During 2017 we reduced the CO2 emissions per kg of goods shipped by 27%. We achieved this through packaging changes; improving our loading layouts; more efficient palletisation and double stacking of pallets as well as using fewer warehouses to reduce the number of shipments.

USE OF ENERGY

Our warehousing and distribution service centre, is located in Denmark. With winter temperatures regularly falling below freezing, heating is essential both to protect our products and make sure our warehouse employees are comfortable. To improve efficiency we have a project looking at a system that will give a more even distribution of the heating helping to save energy and reduce carbon emissions.

In January 2017 we installed LED lighting in our warehouse and offices and expect to save up 112,000 kilowatt hours while actually increasing light volume in sime some areas by 15%. This change to LED-lighting has also meant that visible identification of pallets in the racks has improved significantly and a daylight feeling has been brought into even the darkest aisles in the warehouse.

Achieving sustainability is about taking care of all the details – both big and small so we have made changes that mean that broken pallets, that were previously thrown away, are now sold on so the wood is reused

GOOD CAUSES

In 2017 SPECIFIC became an official supporter of The Ocean Cleanup. The Ocean Cleanup designs and develops advanced technologies to rid the oceans of plastic. Their purpose is to drive the largest clean-up in history through the large-scale, efficient and environmentally-sound removal of plastic pollution from aquatic ecosystems. In 2018 then they deployed their first operational system in the Great Pacific Garbage Patch with the aim of reducing the size of the patch by 50% in only 5 years.

SPECIFIC is also working on a number of projects with The Marine Conservation Society including one looking at levels of marine contamination.